Industrial automation has reached new heights with advanced technologies driving precision, efficiency, and reliability. Among these innovations, the SK 100W-MF2-35-1E1-1S10 / VPL-B1003 configuration stands out as a remarkable solution for motion control in demanding applications. This article delves deep into the key aspects of this system, combining the WITTENSTEIN alpha SK+ hypoid gearbox and the Allen-Bradley Kinetix VPL servo motor, to explore its capabilities, applications, and benefits.

What Is SK 100W-MF2-35-1E1-1S10 / VPL-B1003?

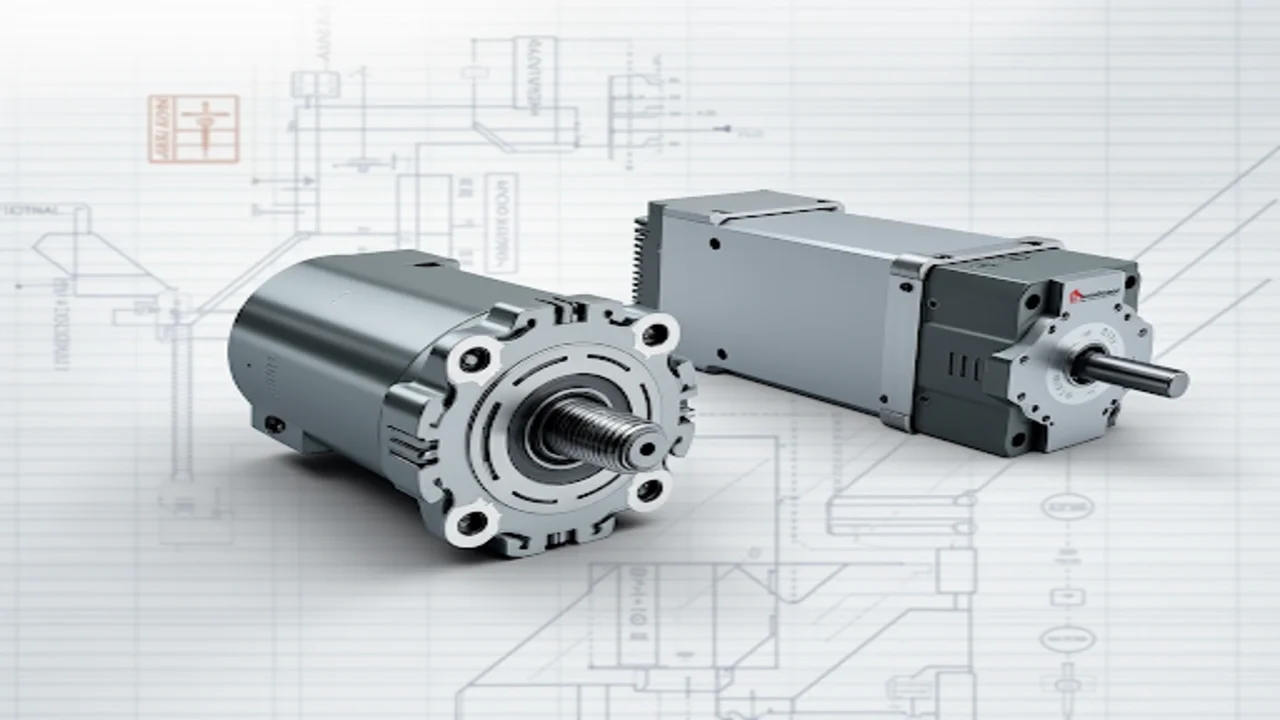

The SK 100W-MF2-35-1E1-1S10 / VPL-B1003 is a powerful industrial automation system designed to deliver exceptional performance in motion control. This configuration integrates the compact and efficient WITTENSTEIN alpha SK+ hypoid gearbox with the highly dynamic Allen-Bradley Kinetix VPL-B1003 servo motor. Together, they provide a reliable, space-saving, and high-precision solution for a wide range of industries.

- WITTENSTEIN alpha SK+ Hypoid Gearbox: Known for its right-angle design, low backlash, and high efficiency, this gearbox supports precise motion control in compact spaces.

- Allen-Bradley Kinetix VPL-B1003 Servo Motor: Engineered for dynamic performance, this servo motor offers features like low inertia, high-resolution encoding, and exceptional responsiveness.

Key Features of SK 100W-MF2-35-1E1-1S10 / VPL-B1003

Precision Motion Control Components

The combination of the hypoid gearbox and the servo motor delivers unparalleled accuracy.

- Low Backlash: Ensures smooth and precise motion.

- High Torsional Rigidity: Minimizes deviations in positioning.

- Dynamic Responsiveness: Adapts seamlessly to rapid changes in movement requirements.

Space-Saving Design

Compact machinery is essential for modern industrial applications.

- Right-Angle Configuration: Ideal for machinery with limited space.

- Compact Motor Frame: The VPL-B1003’s sleek design allows for efficient integration.

High Efficiency

Efficiency is a hallmark of this system, offering both energy savings and cost-effectiveness.

- Optimized Gearbox Mechanics: Minimizes energy losses during operation.

- Advanced Motor Winding: Supports energy-efficient performance at high speeds.

Durability and Reliability

Industrial environments demand robust components, and this configuration delivers.

- Engineered for Longevity: Both components are built to withstand demanding conditions.

- Low Maintenance Requirements: Reduces downtime and operational costs.

Applications of SK 100W-MF2-35-1E1-1S10 / VPL-B1003

Manufacturing Automation

Precision and speed are crucial in manufacturing.

- Assembly Lines: Enhances accuracy and throughput in automated assembly processes.

- Robotics: Provides dynamic motion control for robotic arms.

Packaging Machinery

Packaging systems benefit significantly from this configuration.

- Precise Product Handling: Ensures consistent quality and alignment in packaging.

- Fast Operations: Accelerates packaging lines without compromising precision.

Material Handling Systems

Efficient material transport is vital for productivity.

- Conveyor Systems: Streamlines operations with smooth motion.

- Automated Storage and Retrieval: Improves space utilization and operational efficiency.

Other Specialized Uses

- Medical Equipment: Supports precise and reliable movement in diagnostic machines.

- Semiconductor Manufacturing: Delivers high-precision motion for delicate processes.

Advantages of SK 100W-MF2-35-1E1-1S10 / VPL-B1003

Space Efficiency

Compact machinery layouts reduce footprint and improve functionality.

High Precision and Control

Low backlash and high-resolution encoding ensure precise positioning, critical for advanced industrial tasks.

Energy Efficiency

Optimized designs lead to lower power consumption and cost savings, making this configuration ideal for energy-conscious operations.

Reliability and Durability

Built with industrial-grade materials, this system is designed for long-term use with minimal maintenance.

Competitor Analysis

Below is a comparison table to illustrate the strengths of SK 100W-MF2-35-1E1-1S10 / VPL-B1003 against top competitors:

| Feature | SK 100W-MF2-35-1E1-1S10 / VPL-B1003 | Competitor A | Competitor B |

| Space Efficiency | Excellent | Good | Average |

| Precision | High | Medium | High |

| Energy Consumption | Low | Medium | Medium |

| Durability | Very High | High | High |

| Maintenance Requirements | Minimal | Moderate | Moderate |

Integrating SK 100W-MF2-35-1E1-1S10 / VPL-B1003

Installation Guidelines

- Ensure proper alignment between the gearbox and servo motor.

- Use manufacturer-recommended fasteners for secure mounting.

Optimization Tips

- Regularly inspect for wear and tear to maintain performance.

- Calibrate the motor encoder for maximum precision.

Common Challenges and Solutions

- Vibration Issues: Address by tightening all connections and verifying alignment.

- Temperature Fluctuations: Ensure proper ventilation and cooling mechanisms.

FAQs

What makes SK 100W-MF2-35-1E1-1S10 / VPL-B1003 unique?

Its unique combination of a compact hypoid gearbox and dynamic servo motor offers unmatched precision, efficiency, and reliability.

Which industries benefit most from this configuration?

Manufacturing, packaging, material handling, and medical equipment industries are the primary beneficiaries.

How does the low backlash feature improve performance?

Low backlash minimizes positional errors, enhancing accuracy and consistency.

This detailed exploration of the SK 100W-MF2-35-1E1-1S10 / VPL-B1003 provides insights into its superior capabilities and applications, positioning it as a leader in modern industrial automation solutions.

Also Read: How to Choose the Right Metal for Building Construction

Harold Ayres, a captivating wordsmith and seasoned blogger, weaves tales that transport readers to worlds unknown. With his keen insight and vivid storytelling, Harold’s literary prowess captivates hearts and minds, leaving an indelible mark on the literary landscape.